So far I've spent much of the time on mechanics rather than the electronics. But, I'm not in a hurry and try to get the joy of doing things slow but steady. The chassis is almost done, I'll add some handles and maybe some protective rubber caps, just in case it decides to run away and hit somewhere.

This is the story of my pet robot. The idea came to mind when my sons relentless begging for owning a dog drived me crazy. Instead of having a dog I decided to make one :)

Friday, October 18, 2013

Friday, October 11, 2013

I have two stock motors from Parallax, they are 7.2 volt and 310 rpm. My concern is that they are a little bit faster than I want them to be. I see that many people replace them, anyway. I'd prefer torque over speed, and I think a higher gear ratio will make it more stable. BTW, I'd like to thank Erco for finding the lower rpm replacement motors on Ebay. I guess I'll use the similar ones which are 70 rpms but 12 volt. I don't know yet if my 6 cells 7.2 volt NIMh battery pack would provide enough juice for them.

Monday, October 7, 2013

After a few busy weeks, found some time to work on my robot again. I brushed the aluminum tail that I cut from 2 mm sheet. It looked straightforward in the video I mentioned previously, but believe me it is a long and laborious process. It took me almost half an hour just to brush one side with 180 grade sand paper. The pictures were taken ten minutes apart.

Wednesday, October 2, 2013

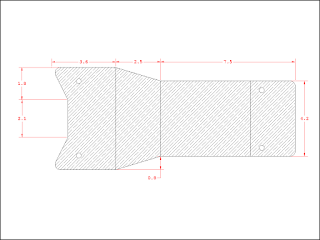

The tail assembly would become sturdier if there is a support from the buttom upward. And here is he solution. It's the same kind of aluminum, 2 mm thick. Cut and filed by manual tools.

I have nothing but an old vise to use for bending. But the trick is; first make a groove around (0.5 mm) on the plate where you want to bend with a dremel cutting disc, and then bend it slowly. Before bending, I made some brushing with 240 grit sand paper. I'm very happy with the result, it's just great, isn't it?

I have nothing but an old vise to use for bending. But the trick is; first make a groove around (0.5 mm) on the plate where you want to bend with a dremel cutting disc, and then bend it slowly. Before bending, I made some brushing with 240 grit sand paper. I'm very happy with the result, it's just great, isn't it?

Subscribe to:

Posts (Atom)